Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

With nearly two decades of excellence, Mountain Steels Pvt. Ltd. stands at the forefront of TMT steel bar manufacturing. Our commitment to quality, innovation, and sustainability ensures that our products not only meet but exceed industry standards.

We source the finest raw materials and employ stringent quality control measures to produce Agniveer TMT steel bars that set the benchmark for excellence.

To be the cornerstone of excellence in TMT steel bar production, empowering our clients to build a better, stronger future through superior technology, high-quality raw materials, and unwavering customer satisfaction.

TMT (Thermo-Mechanically Treated) steel bars are produced through a specialized manufacturing process that enhances their strength, ductility, and durability.

The process begins with the careful production of high-quality billets in our own Induction Furnace. Highly trained metallurgists and quality specialists ensure that optimum chemical composition is maintained. Our billets undergo rigorous testing through a Computerized Spectrometer in our state-of-the-art laboratory.

The Continuous Casting Machine (CCM) transfers the billets to the rolling mill. Continuous casting offers several advantages over traditional ingot casting methods, including higher production rates, improved product quality, and reduced energy consumption. It’s a crucial technology in modern steelmaking, allowing for efficient and cost-effective production.

Once the CCM transfers the hot billets to the rolling mill, they undergo a series of rolling operations, which involve passing them through a series of grooved rollers to gradually reduce their cross-sectional area and shape them into long, uniform steel bars.

After the initial rolling process, the steel bars are rapidly cooled by passing them through a high-pressure water spray system. This rapid quenching stage, also known as quenching, causes the outer surface of the bars to cool quickly while the inner core remains hot, resulting in the formation of a hardened outer layer and a relatively softer inner core.

Following quenching, the bars are subjected to a controlled heating process known as tempering. The bars are allowed to cool in ambient air, which causes the heat from the inner core to transfer to the hardened outer layer, resulting in the formation of a tempered martensitic structure throughout the bar.

Engineered for unmatched strength and durability, our AGNIVEER TMT Bars undergo a rigorous manufacturing process to withstand the toughest challenges. Discover the features that make our TMT bars the preferred choice for construction projects

Produced using high-quality ISI 2830 billets in our on-site Induction Furnace, AGNIVEER TMT Bars conform to stringent ISI standards. We control the quality process from start to finish, ensuring the highest standards in every bar.

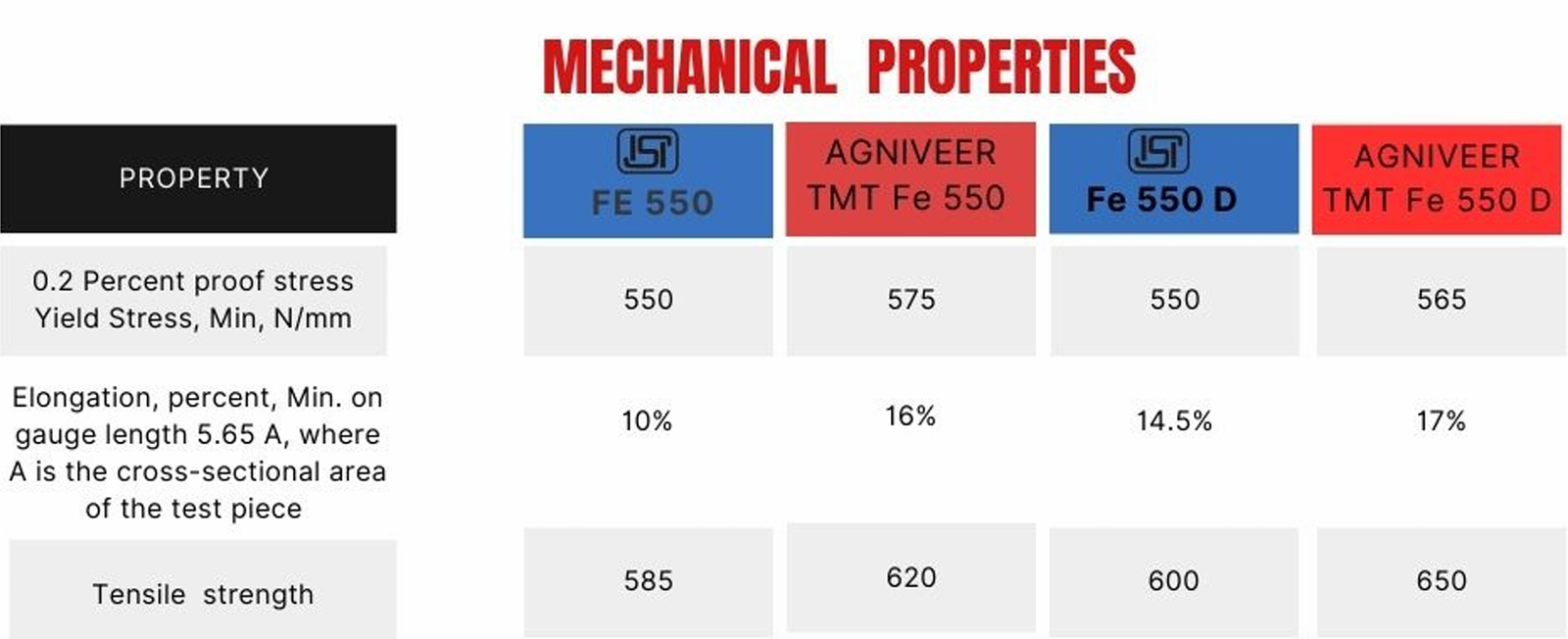

Our Agniveer Fe 550 and Agniveer 550D TMT bars are distinguished by their low carbon, Sulphur, and phosphorus contents, with high manganese and silicon for better ductility, weldability, and earthquake

resistance.

| PROPERTY | ISI FE 550 | AGNIVEER TMT Fe500 | ISI FE 550D | AGNIVEER TMT Fe 550D |

|---|---|---|---|---|

| 0.2 Percent proof stress Yield Stress, Min, N/mm | 550 | 575 | 550 | 565 |

| Elongation, percent, Min. on gauge length 5.65 A, where A is the cross-sectional area of the test piece | 10% | 16% | 14.5% | 17% |

| Tensile strength | 585 | 620 | 600 | 650 |

| CONSTITUENT | ISI FE 550 | AGNIVEER TMT Fe500 | ISI FE 550D | AGNIVEER TMT Fe 550D |

|---|---|---|---|---|

| CARBON | 0.30 | 0.28 | 0.25 | 0.22 |

| SULPHUR | 0.055 | 0.045 | 0.040 | 0.037 |

| PHOSPHORUS | 0.050 | 0.047 | 0.040 | 0.036 |

| MANGANESE | 0.45 | 0.50 | 0.50 | 0.55 |

Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magn.

Michael Wilson - CEO of Tozee

Patricia Bogle - CEO of Manan

Joseph Hyde - CEO of Moiz

Dolores et ea rebum vero eos et accusam et justo duo dolores at ea rebum. labore vero dolore magna aliquyam erat

Dolores et ea rebum vero eos et accusam et justo duo dolores at ea rebum. labore vero dolore magna aliquyam erat

Dolores et ea rebum vero eos et accusam et justo duo dolores at ea rebum. labore vero dolore magna aliquyam erat

Dolores et ea rebum vero eos et accusam et justo duo dolores at ea rebum. labore vero dolore magna aliquyam erat

Dolores et ea rebum vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Siam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. dolores et ea rebum vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. sed diam voluptua. At vero eos et accusam justo duo dolores et ea rebum.

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

At Mountain Steels Pvt. Ltd., we specialize in manufacturing high-quality TMT steel bars, combining advanced technology with stringent quality control to deliver exceptional products for your construction needs. Contact us for reliable, durable, and sustainable steel solutions.

© 2024 Agniveer • All Rights Reserved Dizi Global Solution Varanasi